Material handling is pretty much the most self-explanatory term. As a warehouse owner and a seller, you are constantly on the lookout for ways to manage your product from its processing to its storage and ultimately to preserve its quality. Here are some efficient and tried tested ways to accomplish this goal.

Let’s talk a little bit first about what material handling is. “Material handling is the movement, protection, storage and control of materials and products throughout manufacturing, warehousing distribution, consumption and disposal”.

To make it simpler we have sorted the few basic factors that are most commonly considered while making a top-notch material handling plan.

In our opinion, the most vital factors to improve your material handling system depends on:

- Storage & Handling Equipment

- Bulk Material Handling Equipment

- Implementing A Warehouse Management System

- Organizing Your Space Intelligently

1. STORAGE AND HANDLING EQUIPMENT

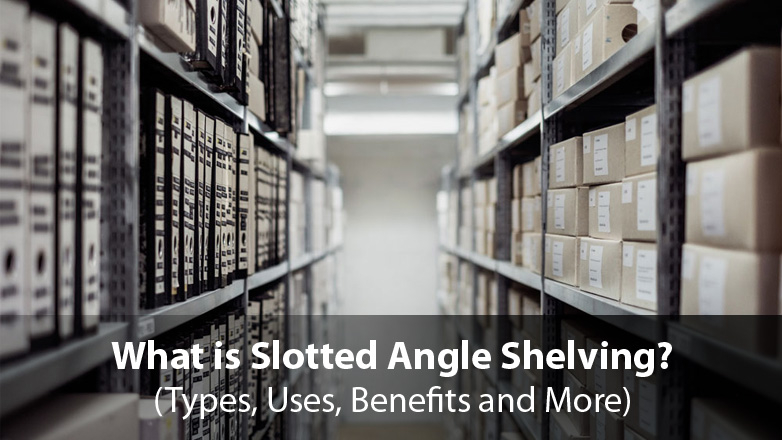

An efficient racking and shelving system is absolutely vital for the storage of your product. What is noteworthy here is, for a smaller and lighter product, and accessible racking system works best.

For a heavier and larger product, you will need a shelving system which usually requires automated handling with wider aisle spaces or no aisles for maneuvering.

Storage shelves must be accommodating and suitable for your product while also providing ease of access to your employees. To accomplish this you may need a racking and shelving supplier.

In the UAE you will be able to find some pretty solid racking and shelving suppliers like the Kheera group of companies and many others that are well versed in industrial shelving as well as hand racking.

Don’t:

Do not place the racking and shelving system cost above the safety and access of your product. Do not hesitate to invest in a good racking and shelving system because this will be home to your products until sent out for sale.

2. BULK MATERIAL HANDLING EQUIPMENT

Most of your material, at some point, is going to be in a loose bulk form. This will require maneuvering and processing on a larger and faster level. To accomplish this you may employ:

- Industrial trucks: Industrial trucks are ideal for the transport of loose bulk items that would otherwise take hours being passed around by hand or inboxes. Automated guided vehicles fall under this category and are extremely popular. These trucks are efficient for carrying loose products, pellets, or large products.

- Conveyor belts: A conveyor belt is an engineered system that can be morphed into a more complicated system to maximize your processing efficiency.

- Stackers and reclaimers: These are large machines that are used to dump materials into piles that can be picked up again. A little difficult to visualize but they make a lot of sense in a warehouse.

Don’t:

Do not think of storage handling equipment as a quick fix to all your warehouse problems. Expect downtime and breakdowns with machines. Keep in touch with mechanics and machinery experts.

3. IMPLEMENTING A WAREHOUSE MANAGEMENT SYSTEM

Implementing a warehouse management system needs firstly for you to be practical and realistic about your expectations regarding the trajectory of your production.

Setting realistic expectations and objectives will help you scale the progress of your business for future reference and to get a progressive outlook.

Implementing a warehouse management system will get you working in close proximity with an implementation partner.

This will require you to trust him as much as you would with a doctor fixing your sprained ankles. It might seem complex but with the right partner, it is possible.

After clearly spelling out your expectations and implementing the warehouse management system you must regularly assess your system for potential risks. Your focus must then shift to meticulous execution and employing skilled program managers.

Don’t:

Do not lose faith in your management system while experiencing a few bumps. This is a

system of trial and error. There will be modifications in the process. Stay flexible and assess realistic risks while slowly eradicating them along the way.

4. ORGANISING YOUR SPACE INTELLIGENTLY

Your central focus while selecting a racking and shelving system for your warehouse should always be in alignment with your product, your budget and your workforce.

A huge part of organizing your warehouse is identifying your limiting factors and eradicating them. Visual memories are the strongest with humans so putting name cards, tags and labels is a huge yes.

Organize your product based on the frequency of access. The products used most must be kept in the front. Making use of vertical height by stacking your product makes a lot of sense.

This especially makes sense if your product is sent out in regular intervals of time. You can have separate shelving or racking for seasonal or limited edition products.

Keeping bins and containers for small and easily misplaced tools will help in keeping loose articles away from the aisles, thus avoiding freak accidents and injury to your employees.

Don’t:

Do not become overzealous with the concept of tags and craftwork. Keep the directives simple and clear. Avoid putting in excessive directions that complicate the process. Take into consideration various factors that have a tendency to create confusion and hindrance.

Conclusion

A warehouse becomes a living breathing system once in action. You can keep it organized and

updated but you will observe downtime and breakdowns. To battle this the ultimate key is to stay hands-on and flexible with your processing system.

Include and exclude systems based on your needs while scaling your progress with each modification. Ultimately this is a process of trial and error.

So after a few bumps and errors, you will have in your hands a material handling system that is absolutely unique and efficient to your business model and product.

Leave A Comment